Case Studies

Special service for relocating medical equipment to high locations.

"We would like Ohmura Sogyo to assist us with the installation of equipment in an area with limitations."

Our customer needed to install medical equipment on the 4th floor but was unable to use the elevator due to space and weight restrictions. They requested that we explore possible solutions to bring the equipment in through a service entrance located on the outer wall of the 4th floor.

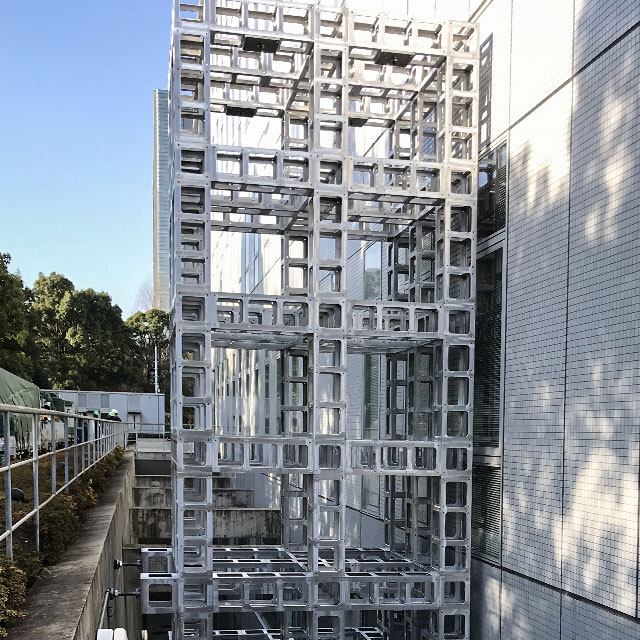

The construction of a temporary platform was carried out to provide a secure access point for moving in the equipment

We proposed an execution plan that involves using a large crane to directly lift the equipment from the ground to the service entrance on the 4th floor, which is 12 meters above ground, once the platform has been constructed.

Integrated services that optimize delivery conditions

By utilizing safe and reliable techniques to meet our customer’s requirements, we maximized the delivery conditions of the facility and successfully installed the equipment as planned.

This case study illustrates our integrated services encompass every aspect, from packing and transportation to installation.

Bringing in and installing large medical equipment on temporary rails

Example of large medical equipment delivery via temporary rails

In this case study, we successfully delivered medical equipment into a medical facility through its terrace. We installed temporary rails on the upper section of the terrace and utilized a jig to carefully move the heavy equipment in, ensuring that we accounted for the width of the entrance throughout the process.

Optimizing costs in the transportation of extremely large machinery

"We want to reduce transportation costs for a large machine that is over 11 meters long and weighs more 20 tons"

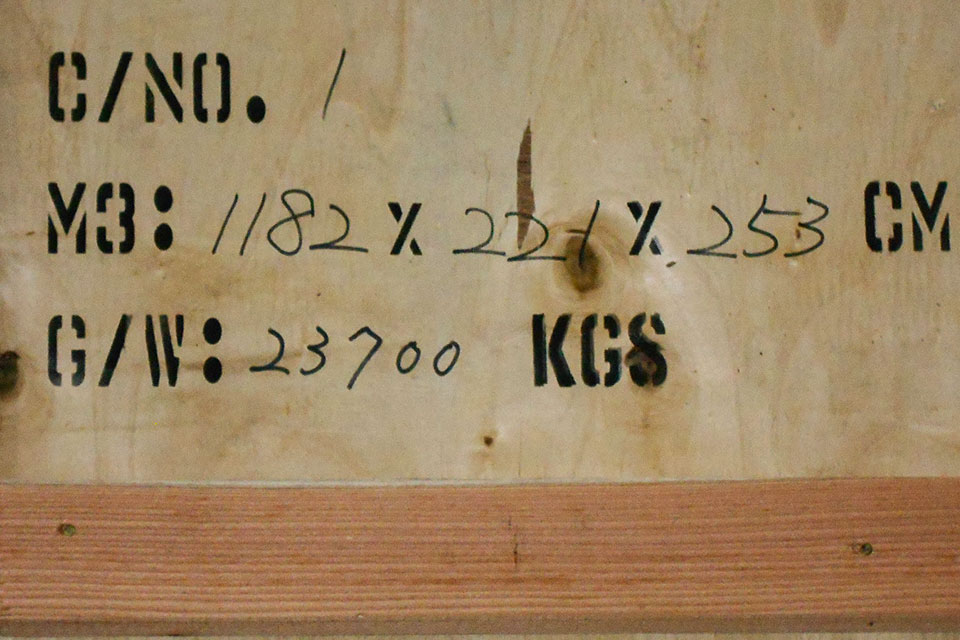

Our customer sought a cost-effective solution for exporting a large machine that is over 11 meters long, 2 meters wide, 2.4 meters high, and weighs more than 20 tons.

Dimensions: 1,182 x 221 x 253 cm, gross weight: 23,700 kg

Designing and constructing custom-made hybrid packaging to meet our client’s request

Taking into account the local cargo handling capabilities, we proposed that the client export the machine using a 40-foot dry container. We also designed and constructed hybrid packaging to facilitate transportation by container ship.

Successful reduction in transportation costs

We utilized steel for the lower section and ceiling to ensure it fit within the height of a high-cube container (253 cm). To reduce friction during forklift insertion, we designed the lower part with rounded edges.

By implementing these modifications, we effectively addressed our customer’s request, enabling transportation via container ship and achieving substantial savings on transportation costs.

Environmentally-friendly transportation and cost reduction

"Is there an environmentally friendly transportation method that meets strict environmental regulations?"

We received a request for an environmentally friendly transportation method that complies with the standards of countries and regions with strict environmental regulations.

Packaging that leverages the characteristics of reinforced cardboard

We proposed that the client transition to reinforced cardboard packaging (Tri-Wall boxes) as an environmentally friendly transportation option. This lightweight and durable type of water-resistant cardboard maintains its strength even when exposed to light rain, making it ideal for delicate products such as leather goods.

Sustainable solutions that reduce transportation costs

By providing solutions tailored to the environment, we not only protect our customers' shipments but also achieve eco-friendly packaging and transportation, which further reduces air transportation costs.